Digital technology has revolutionized marketing throughout the world. Entire industries are developing that did not exist as few as ten years ago. Search engine optimization and marketing are tailored to increase a website’s visibility on search engines. An entire industry is devoted to improving search results. That’s how important the internet is to marketing. However, the older ways of marketing have not become completely obsolete. In fact, they have become more important and more efficient since digital technology has improved the techniques. Printing services, for example, have completely improved in the last decade.

Improvements

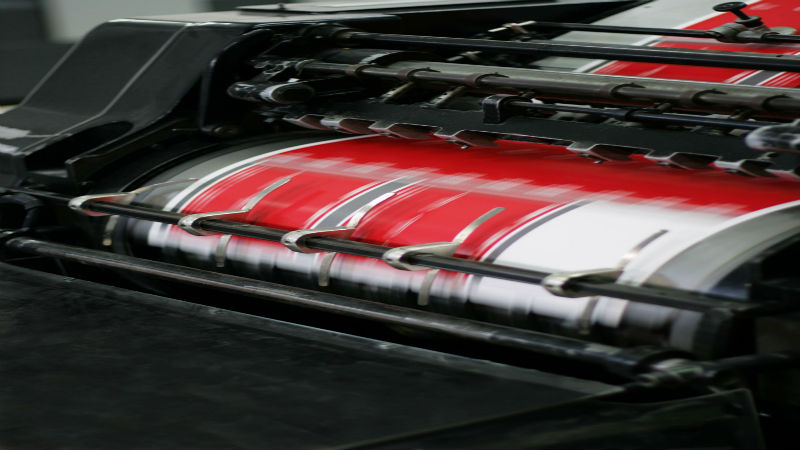

Solvent ink is one of the main improvements in printing services. In a nutshell, solvent ink is an ink that is not made from a water base. This is important because it adheres very well to non-porous surfaces and is not water-soluble. Adhering to non-porous surfaces is important because that makes it perfect for use on vinyl billboards. That also means that it does not break down when exposed to rain. It is also resistant to sunlight. Since it is not water-soluble, it does not break down when it is rained on. UV inks are also somewhat effective at these, but they are not nearly as effective as solvent ink. When used on vinyl billboards that are placed outside, UV inks break down after about a year. Solvent ink lasts for more than three years. This obviously depends on the climate and how long the ink is exposed to the weather. A printing services in Norman, OK will have different considerations from billboard printers in New York, NY because they have different climates.

Components of Solvent Ink

Solvent ink is made of three distinct parts. It is made of the resin, pigment, and the carrier fluid. The term “solvent ink” only refers to the oil-based carrier in the ink but it is used to refer to the entire thing. The carrier dissolves when applied to a surface. The pigment is a powder that is kept in suspension in the solvent. The resin is the means of sticking the pigment to the surface and also the protection for the pigment. The three stage process means that the pigment is glued and protected by a strong material and that there is no water component.

Seamless Vinyl

Some companies use different vinyl panels to construct their billboards. However, seamless vinyl is greatly superior to seamed panels. Seamed panels are more susceptible peeling off the face of the surface. This is because the seams, though small, still create some turbulence when they’re exposed to the wind. This wind eventually will pull the corners of the seams off the surface. Once the ripping or falling starts, then it escalates more quickly. Seamless vinyl is slightly more expensive and more difficult to produce, but current technology makes it possible.

Solvent ink is one of the main improvements in printing services. For more detail about inks contact on (405) 928-5800 or Sitename.