Condensation may seem like a small side effect of a cold glass of water resting in a warm environment. But, it can be a major hazard in a manufacturing environment. Keeping water out of the machinery is impossible. Keeping the air dry and filtered is the only logical way to dissuade and discourage the presence of thick condensation.

What are some of the most practical and common places where condensation can cause a complication? Air Center Inc. isolated four areas where condensation in Air Compressor Accessories PA can potentially destroy the equipment.

• Air receivers: The constant flow of air through the filter creates the perfect place for water to condense. A side-job of an air receiver could be to subjugate condensation to another area entirely, with a dripping pool built in.

• Dryers: Many manufacturers are using a refrigerated dryer. The cool air of the refrigeration is not clashing with the natural air of the warehouse and manufacturing space. The dryers are the main source for condensate, and a refrigerated dryer is a perfect answer.

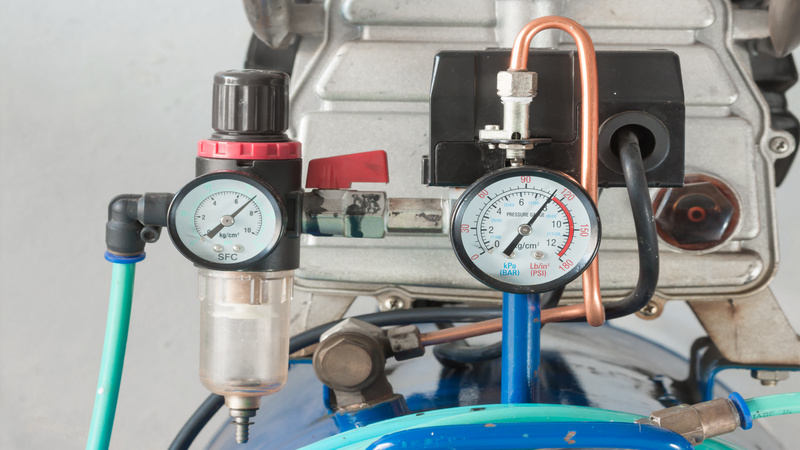

• Controllers: Both manual and automatic flow controllers can help detect where condensation is accumulating and what to do about it. A manual override could potentially control proper flow and minimize water.

Manufacturers will use inline filters for their Air compressor accessories In PA to fight the issue. Lubricants can actually be a practical solution for reducing condensate. They are considered an active response and will require an assigned member to lubricate the equipment daily. There are more active and automatic options available, of course. Condensate filters are an obvious and affordable answer.

Now, it is possible for nearly any equipment to be damaged by condensation. But, the above indicates the places where the heat and the cool create an environment for water to disburse. There are also many small orifices in the equipment where water can proliferate and create damage. Visit us website for finding methods to tackle condensation. In the right environment, it can be a whole lot more than a mild nuisance. With the ability to corrode machinery and freeze lines, poor condensation management could cripple a company and break monthly budgets.