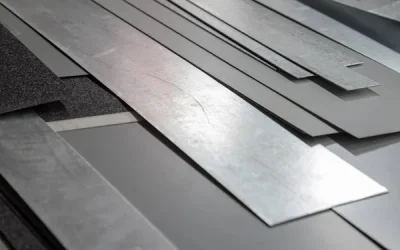

Aluminum is fast becoming one of the top choices in the metal work and development industry, especially for custom aluminum fabrication. That’s not a surprise, though, given the slew of benefits it brings to the table. Here’s some of the benefits you can expect:

High resistance to corrosion

Aluminum demonstrates high resistance to corrosion. So parts aren’t going to succumb easily to corrosion brought on by exposure to rough working conditions, temperatures and climates.

Lightweight

It’s lightweight so it doesn’t add unnecessary heft. That makes it a whole lot easier and convenient to use than steel. Since it requires less manpower and effort to move, it also makes for a better option for many custom aluminum fabrication applications and work environments, especially for oil production industries and truck body manufacture, among others.

Polish

While aluminum doesn’t need to be applied with a finish, it can be polished and painted before undergoing electroplating. That’s how beer and soda companies put in labels on their aluminum cans, says How Stuff Works. So if you’re interested in achieving the same for your fabrication needs, opting for aluminum is a good start.

Durable

One of the best things about aluminum is that it’s pretty durable and sturdy. So you won’t have to worry about parts breaking down or succumbing to wear much too soon. That’s the kind of reliability you want with your aluminum products.

Non-magnetic

The sheet is also non-magnetic so if that’s the kind of material you need for your parts, no worries. With so many options to choose from online, you’re sure to find right provider for your aluminum parts and products soon.

Just remember that to go with a credible provider for your aluminum fabrication services. That way, you’ll be sure that the quality of the resulting work will be top-notch.