If you’ve ever heard of a mica ceramic heater, you already know that they are popular when it comes to certain industrial heating jobs. Why? Because they are very cost-effective and offer uniform heating as well. The mineral known as mica has a lot of resistance to moisture and light and will help the heating elements heat up quickly. Kitchen toasters and space heaters are just two of the devices that tend to use this type of heating, but they are used in many more items as well. They are indeed very versatile heaters that are used in sealing equipment and packaging, to name a few.

What Else are They Used For?

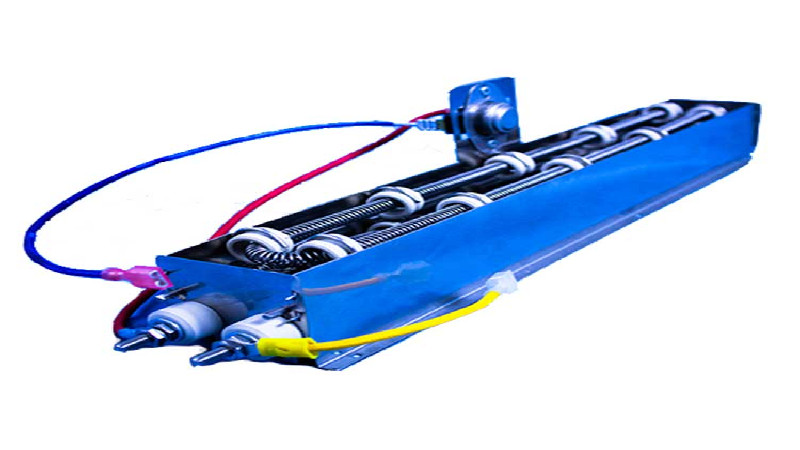

Mica heaters made out of ceramic help heating elements cool and heat up quickly, and they can be used in semiconductor processing, DNA thermocycling, strapping, and even in food service appliances. They are customizable and have fast processing times, and they can reach temperatures of up to 1112 degrees Fahrenheit. Ceramic mica heaters also have a watt density that is higher than conventional mica heaters—up to 110 W/in2—and therefore have a faster processing time.

Do the Research First

Mica and mica ceramic heaters each have their pros and cons, so it’s up to you to decide which ones are right for you. Even though a high-quality mica ceramic heater and standard mica heater are very much alike in a lot of ways, they do have their differences, but there’s enough research available to help you make this decision, especially if you start online.