Plastisol transfers have enthralled many companies and shirt makers. These transfers are cost-effective and ideal for any basic garment creation. This simple, yet innovative method produces noticeable designs that speak to consumers with authority and zeal. However, prior to using the ink contained in plastisol transfers, one must research their function, benefits, disadvantages, and composition.

The Advantages of Plastisol Transfers and Inks

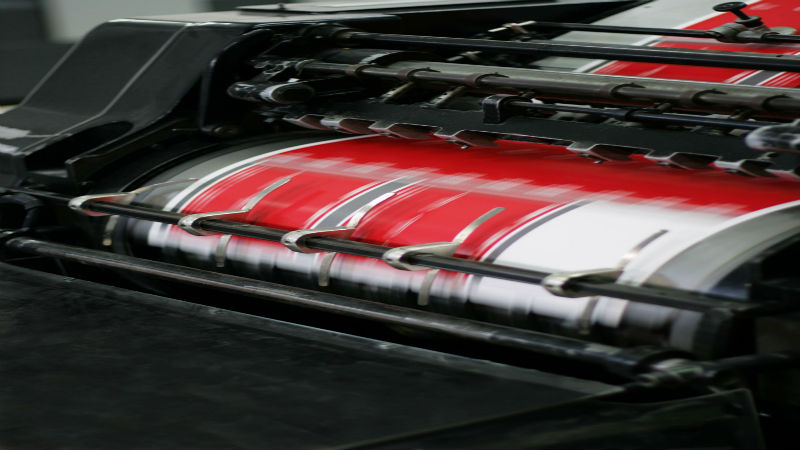

Plastisol inks are one of the most commonly used substances in the shirt making industry. They facilitate the printing process and project themselves brilliantly on dark colored clothing. This type of ink even attaches readily to textiles. The composition of plastisol inks mainly accounts for its clear advantages, as it contains PVC resin and plasticizer.

One small inconvenience is that these inks require elevated temperatures in order to dry properly, hence the purpose of a heat press. However, with the aid of a heat press, plastisol transfers can be completed seamlessly and without hassle.

When cared for properly, the ink in plastisol transfers is relatively harmless. They rarely have air polluting properties or have caustic ingredients. Plastisol inks are not associated with any known injuries or illnesses, as long as appropriate safeguard measures are taken.

Plastisol heat transfers including hot-split, cold-peel and puff methods. Hot-split transfers involve the immediate stripping of the transfer paper, once it is applied to the garment. Once the ink layer is separated, a portion of the ink remains on the garment, while the remaining portion stays on the transfer paper. These prints are very similar to soft-hard direct prints.

Cold Peel transfers operate quite differently. When they are applied to a fabric, they must cool prior to paper removal. The advantage of using cold-peel transfers is that they can produce a glossy or glittery appearance. Puff transfers are unique because they require the use of specially designed puff transfer inks. Once the transfer is complete, the result is a distinguishable puff design.

Concerns about Plastisol Transfers

There are a few cautionary recommendations, however. Mixing additional substances or chemicals into plastisol ink can prove hazardous. Not only can this disrupt their chemical integrity, but it can prevent them from drying or displaying properly on garments. It is never advisable to add mineral spirits, as they can harden the resulting image on the garment. Plastisol inks are generally stored at room temperature.

One particular concern among shirt makers is the issue of dye migration. When dye migration occurs, it generally afflicts polyester materials. Colors composed of plastisol ink migrate in response to heat, causing them to bleed under specific conditions. It is never advisable to dry clean these prints, due to the high temperatures and their effects. Furthermore, they should not be ironed on the printed area.